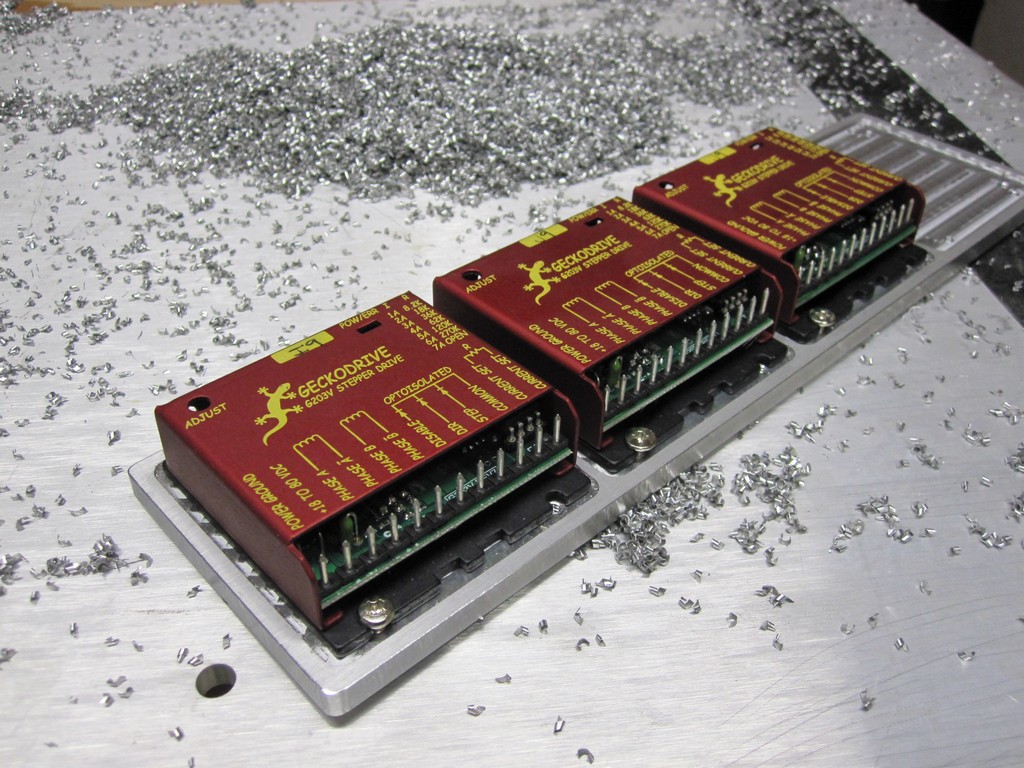

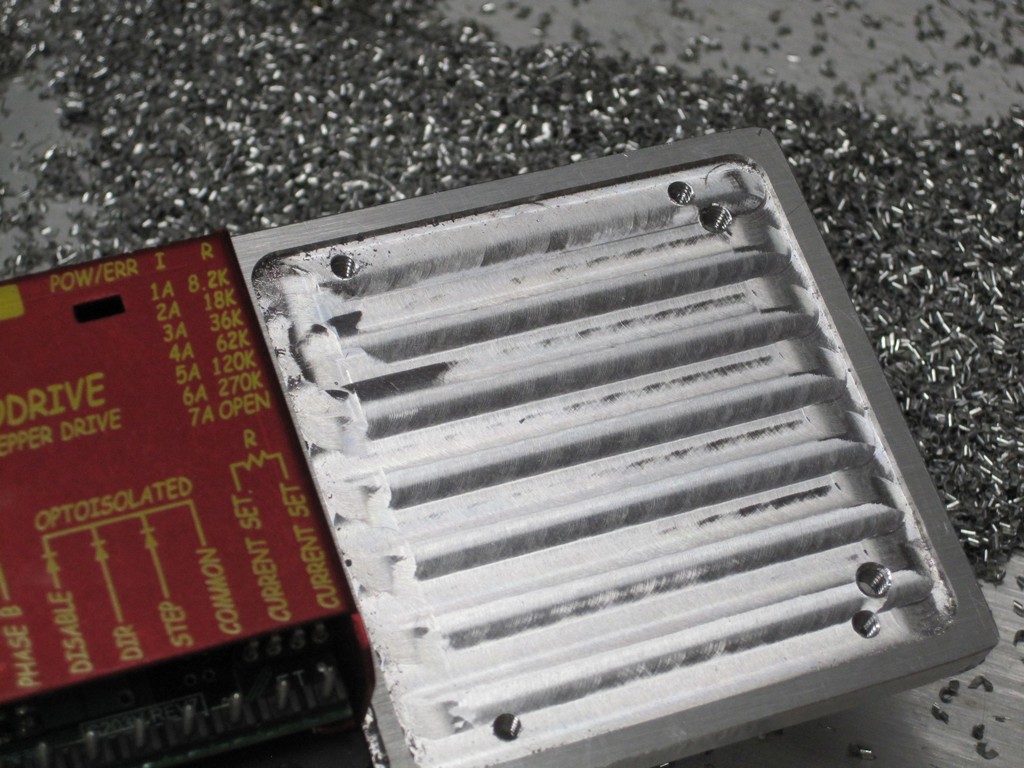

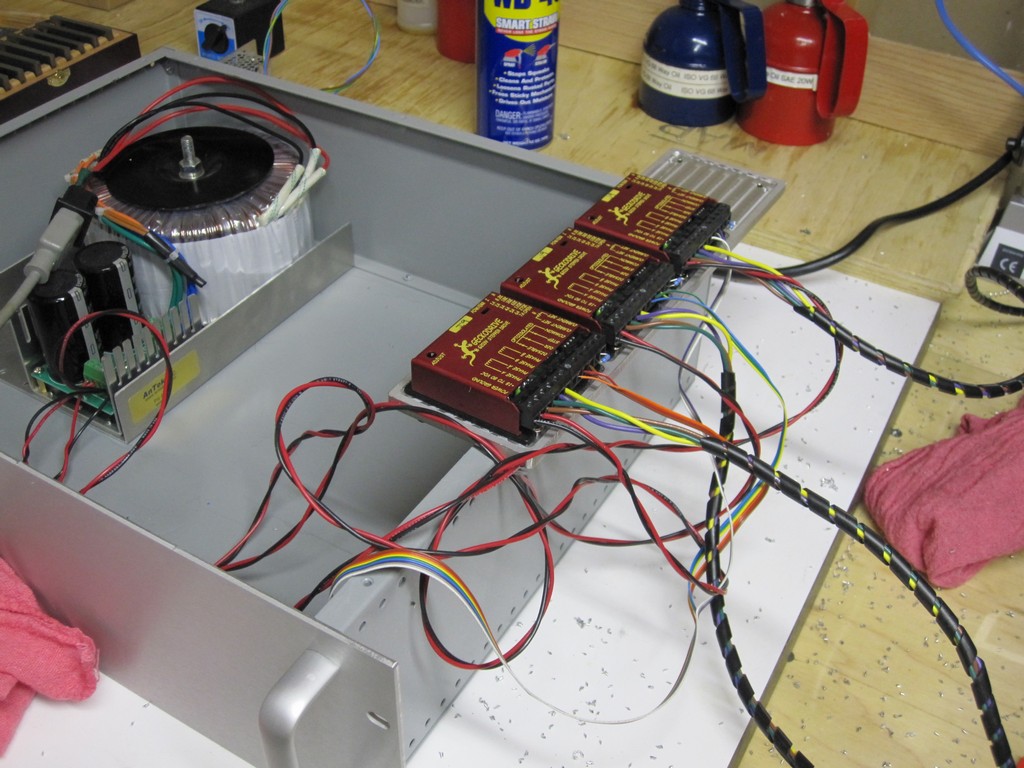

I made my first part out of aluminum last evening. I’ve been slowly designing the electronics enclosure, and I needed a means to mount and cool the GeckoDrives. I designed a mounting plate/heatsink for them, and ran it out of 0.260″ aluminum plate that I happened into as a discard. There are definitely still some things to work out with the CAM process – I broke a couple of center drills due to too-high feed rates, and my gibs definitely need some adjustment, as I got some pretty ugly looking chatter on the profile cutouts. I can feel the slop in the gibs at this point, so I need to spend some time carefully fine tuning the adjusters.

Here’s a time-lapse video of running the part.