Here’s a quick video I did of my first experiments with drag soldering using a new Metcal hoof tip that I picked up on eBay. This video only shows the technique on Small Outline (SO) packages, which are pretty easy to solder by hand, regardless of technique. With minor alterations in technique, drag soldering works great on finer-pitch parts such as TSOP, QFP, etc.

[youtube GN16QVy1z1g]

Drag soldering is the best. You’d be surprised, even in my industry (assembling circuit boards) how many people don’t know about drag soldering. They get very comfortable with letting the stencil of solder paste and the reflow oven do the work. They forget how important it is to know basics like this. I used to get so many people asking me for solder wire with a 0.010″ diameter because they thought that was the only way to solder something with a 15 mil pitch. Drag soldering people! It’s a thing.

Nice job on the video. Thanks for sharing.

I’m completely sold on it, it’s like magic! I’ve switched over to using drag soldering for just about everything that has leads – SOIC, SOP, TSSOP, QFP, etc.

I’ve been doing electronics assembly and rework as a hobby and as part of my job for years, but I’ve learned some new techniques and bought some new gear in the last year that have made life way better.

– Tacky flux paste and a hoof tip, for drag soldering

– Cheap hot air tool for my home lab (previously only had access to one at work)

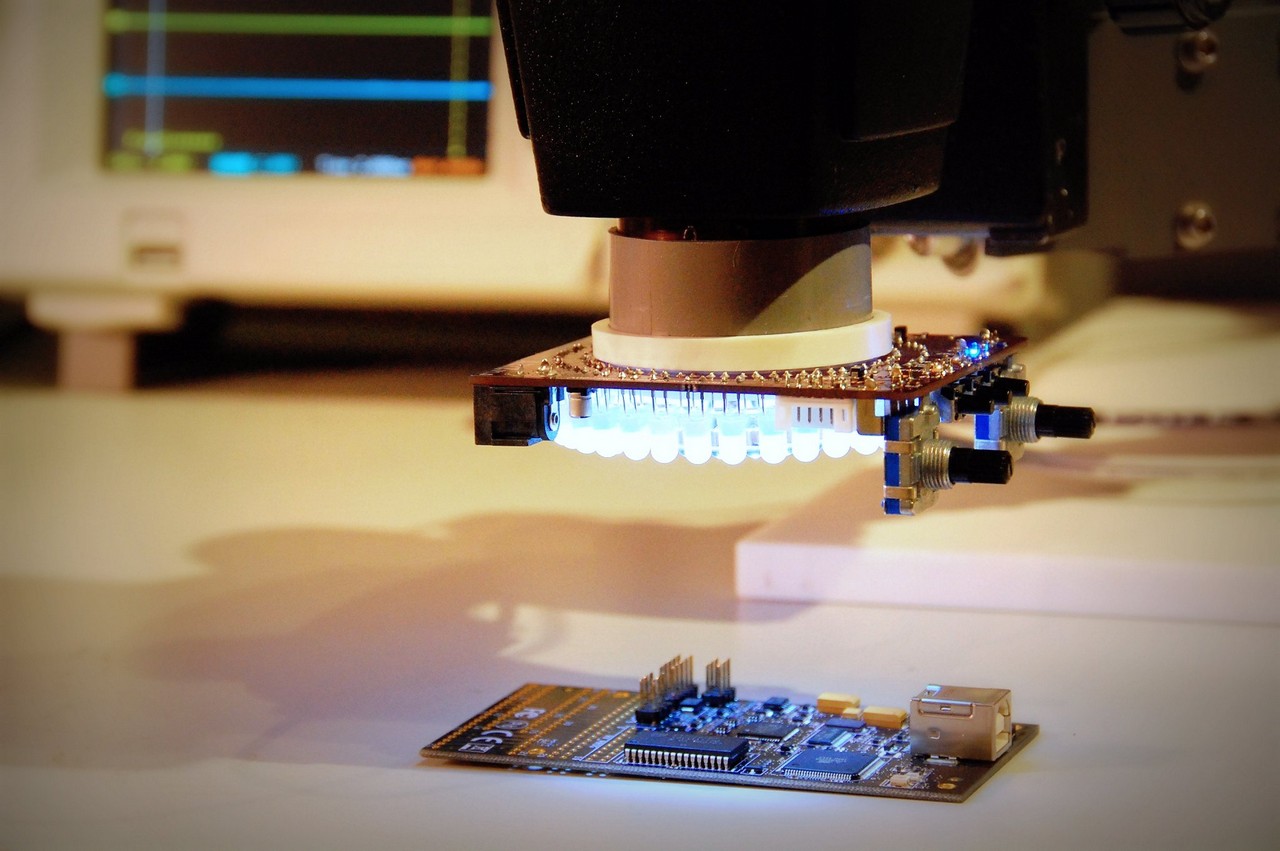

– Stereo microscope for my home lab (same as above… was suffering with a cheap magnifier lamp at home for years)

– Pneumatic solder paste dispenser

It’s really important to keep learning new techniques! Someone else out there almost always has a better, more efficient way of doing things.

Next on my list is hacking together a vacuum pickup tool, and setting up “boards” of cut tapes, like Mike does:

http://www.youtube.com/watch?v=pdGSFc7VjBE