So the CNC conversion is really not quite done, even though I’ve been using the machine to create parts. Still lots of cleanup, fine tuning, and other such tasks to be done.

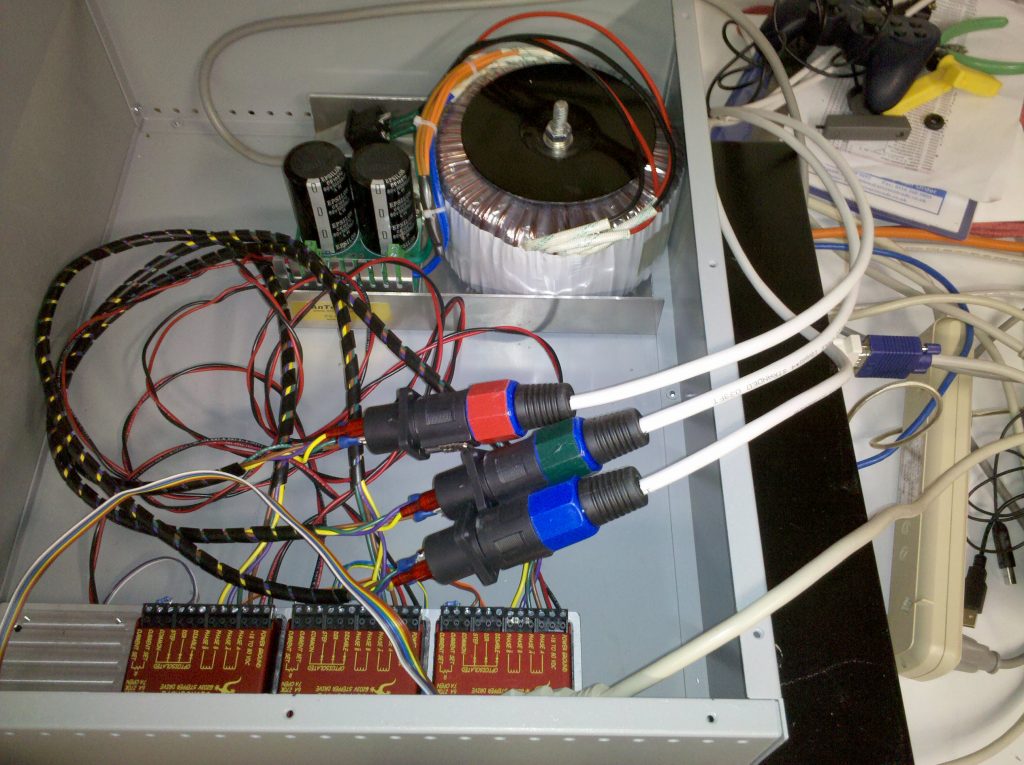

Over the last couple of weeks, I’ve tackled the task of buttoning up the stepper motor wiring. This entailed doing some machining on the rear panel of the mill to add Speak-On jacks (nice robust twist-lock style jacks, one per axis). I also machined up a small plastic cover for the old Z axis handle, through which some split loom tubing passes to connect to the Y stepper. There’s also a piece of split loom tubing connecting the X axis motor to a strain relief on the rear panel. Lastly, I made up some long lengths of 4 conductor cables with Speak-On plugs, to cable back to the CNC controller enclosure. The controller box is one of the next major projects to tackle.