Since 2009, I’ve been messing around with CNC machines. I started out with a small manual milling machine from Grizzly, and converted it to CNC using a kit for the mechanical parts and building my own electronics. You can read about that from the very beginning right here.

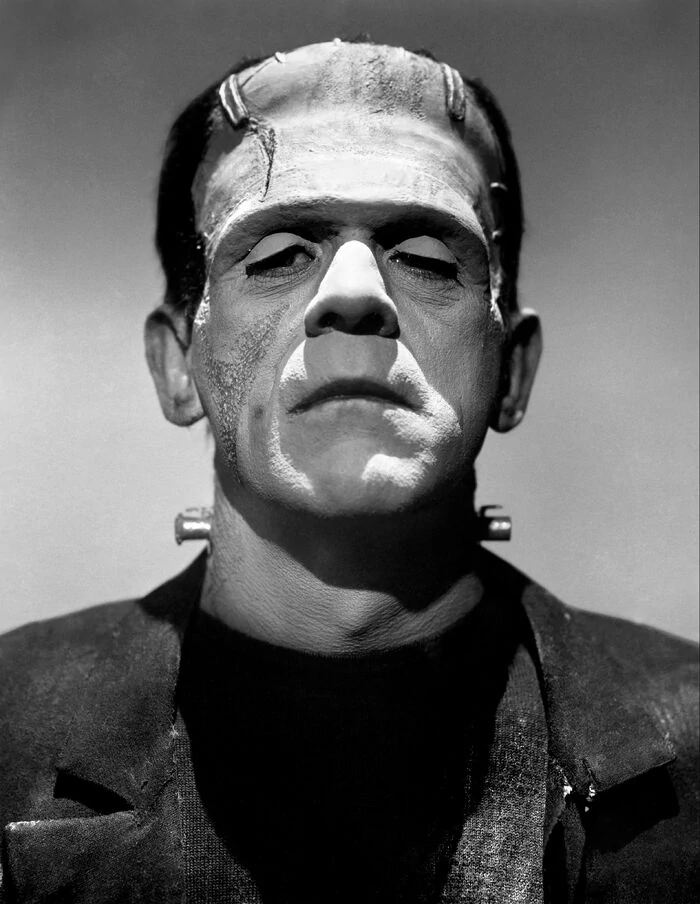

Over the years I’ve done a bunch of minor and major tinkering, culminating in a fairly insane project of grafting on a spindle and head from a Tormach 770 machine in late 2013. I consider this the point where the machine went from being merely a run-of-the-mill converted Sieg X3 machine to a proper one-of-a-kind Frankenmill.

This was the last large project I did to the machine in my pre-MakeIt Labs days. I joined MakeIt a year after the Tormach head transplant, and hoped to use some of the tools there to continue that project… but, stuff happened. I got really involved with helping run the space, and the projects there dominated a lot of my project time for years. Plus, we bought a Tormach 1100 in 2016, so my need for a home machine was reduced somewhat, save for those days when I wanted to make parts without changing out of my pajamas.

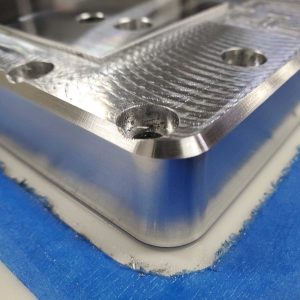

Now, a decade later, I decided it was time to pick up where I left off, and put my new skills and the resources at MakeIt to good use. I wanted to tackle the project of fixing the poor quality dovetail ways on the Z axis of the mill by converting it to linear rails. I planned to use many resources at MakeIt, such as the Bridgeport mill, Tormach CNC mill, and our shiny new waterjet machine.

In the mean time, I also embarked on a bit of labor to import and minimally edit a pile of old forum posts from the CNCZone, where I originally documented the Tormach head project, and had also started to document this new project. That forum is rather dead these days, so I think my own equally dead blog is probably a better home for documenting this journey, since at least it’s mine and I control it.

So, I present a 30-part (and growing) series on Project Frankenmill. The first series of posts are about transplanting the Tormach head. Then, after a brief decade pause, it picks back up with the column linear rail conversion project.

Now, choose wisely.