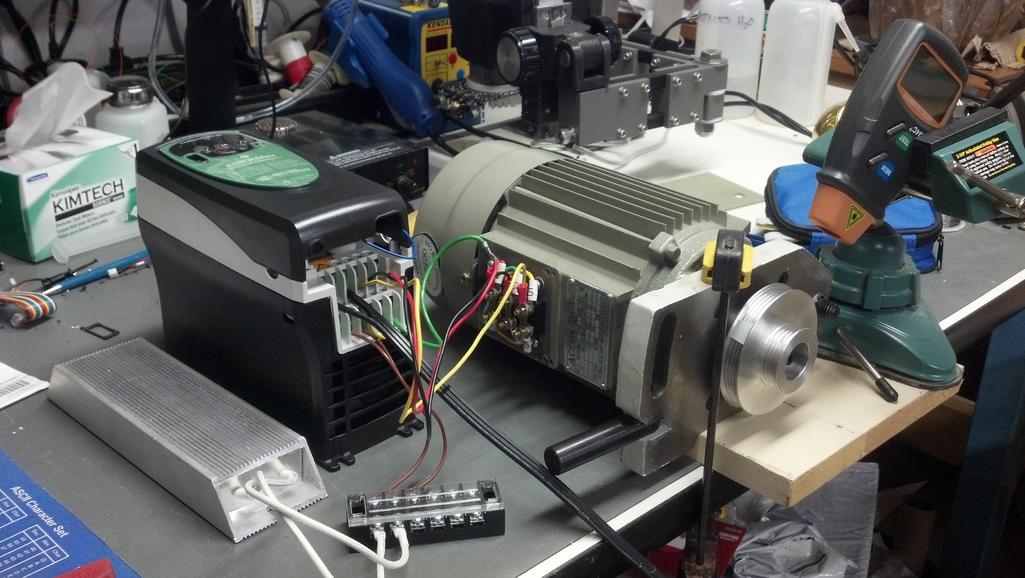

My VFD showed up today, so I got it up and running with the Tormach motor. No real mystery to wiring up the basics: 120VAC single phase in, 3 phase wires to the motor, and some earth grounds. Had to set a few basic parameters to get the motor spinning the first time. Took some further tuning to speed up the acceleration/deceleration, and enable braking on stop.

Some research turned up that LinuxCNC does have some rudimentary Modbus RTU support, so I figured I’d mess around with that (being the software/electronics geek that I am). It took some doing to get RS485 working properly on the embedded motherboard that I use in my control. There’s a combination of physical jumpers, BIOS settings, and non-standard cabling to get it running properly.

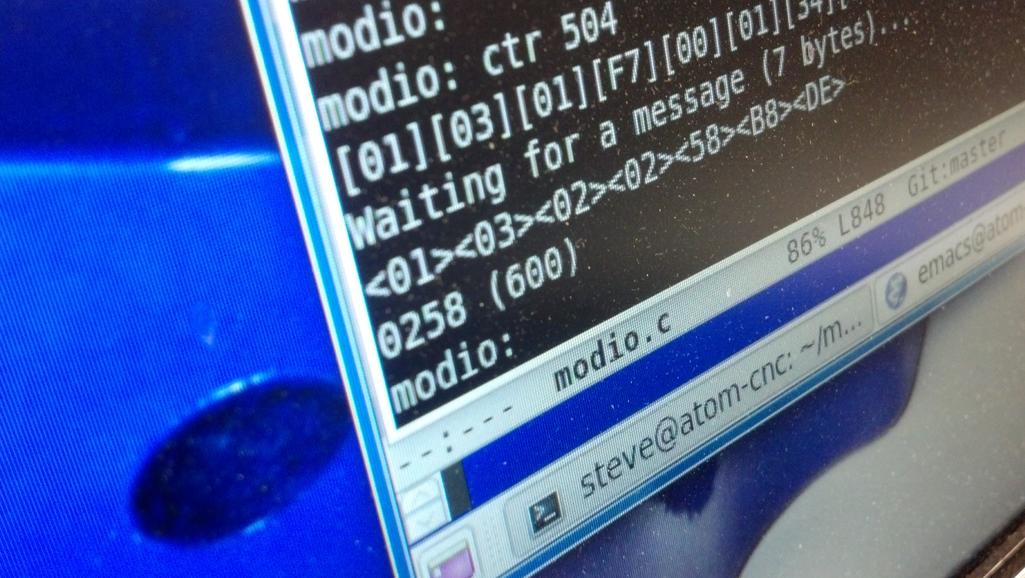

For early debug I’m using a utility called modio that lets you issue Modbus commands and query registers. It took more work to get my first basic query to work, and then a bunch more effort to figure out the basics of how the Control Techniques VFD uses its registers. I wrote some code and modified the modio utility to make this easier.

The upshot of all of today’s effort is that I can run the motor forward, reverse, and set the speed all under computer control.