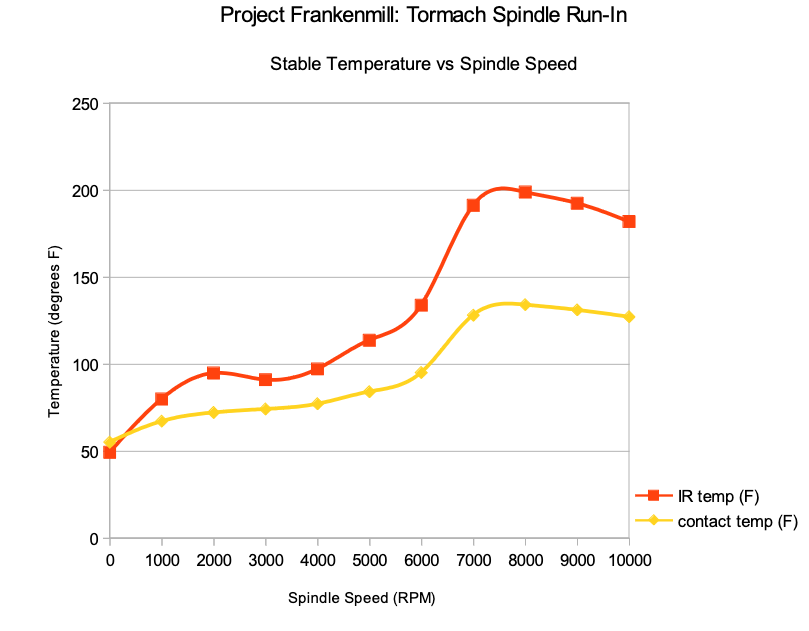

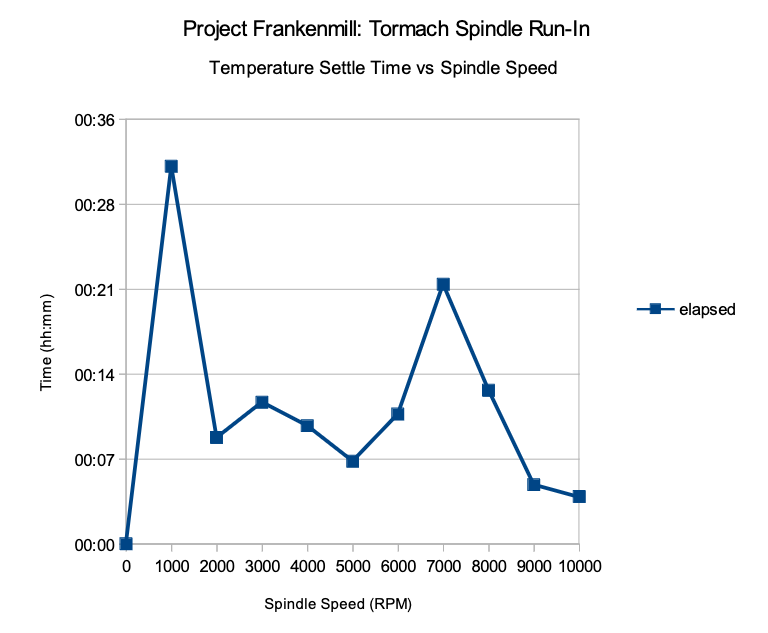

In my talking with Tormach, I asked about a spindle break-in procedure. They told me it should have already been done, but it wouldn’t harm anything to do it again. They suggested running it in 1000RPM increments, and measuring the spindle temperature with a non-contact IR thermometer. Once the temperature stabilized at a particular speed, bump it up to the next one.

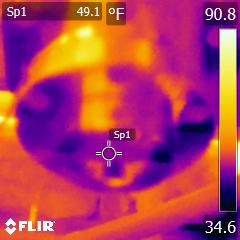

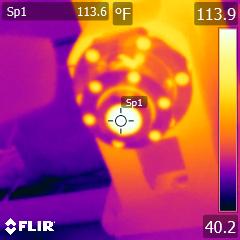

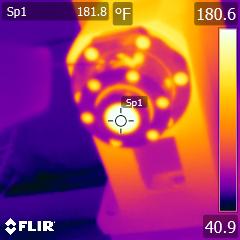

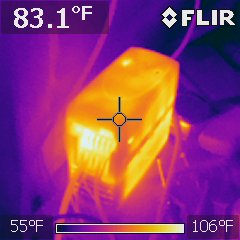

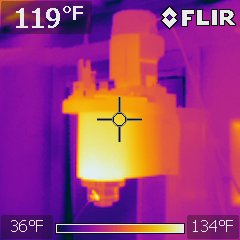

I figured I’d one-up it a bit and get some IR imagery while I was at it, as well as get thermocouple data off of the stationary part of the spindle nose. Here is my test setup. It’s just a multimeter with a temperature probe, and a Flir i7 handheld IR camera I borrowed from the lab at work.

I collected IR images and data at each speed level and did some charting and graphing during the break-in process.

Who doesn’t love data?

2013DEC12

time elapsed speed IR temp (F) contact temp (F)

07:06:00PM 00:00 0 49.1 55

07:38:00PM 00:32 1000 79.8 67

07:47:00PM 00:09 2000 94.7 72

07:59:00PM 00:12 3000 90.9 74

08:09:00PM 00:10 4000 97.1 77

08:16:00PM 00:07 5000 113.6 84

08:27:00PM 00:11 6000 133.8 95

08:49:00PM 00:22 7000 191.1 128

09:02:00PM 00:13 8000 198.8 134

09:07:00PM 00:05 9000 192.4 131

09:11:00PM 00:04 10000 181.8 127