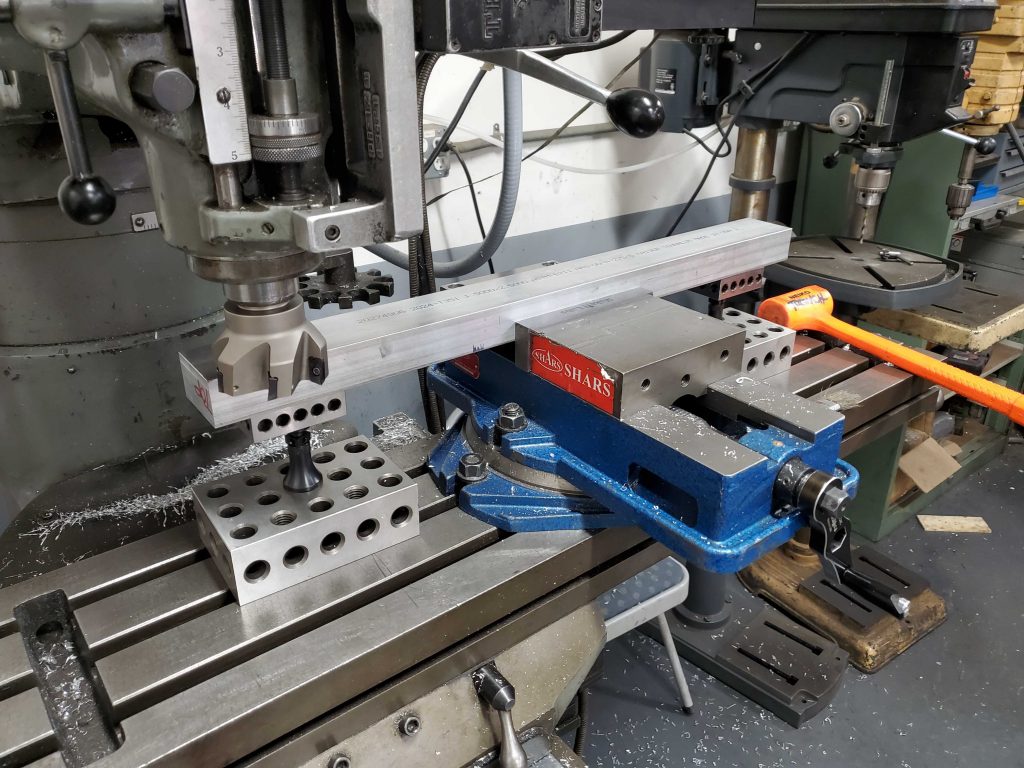

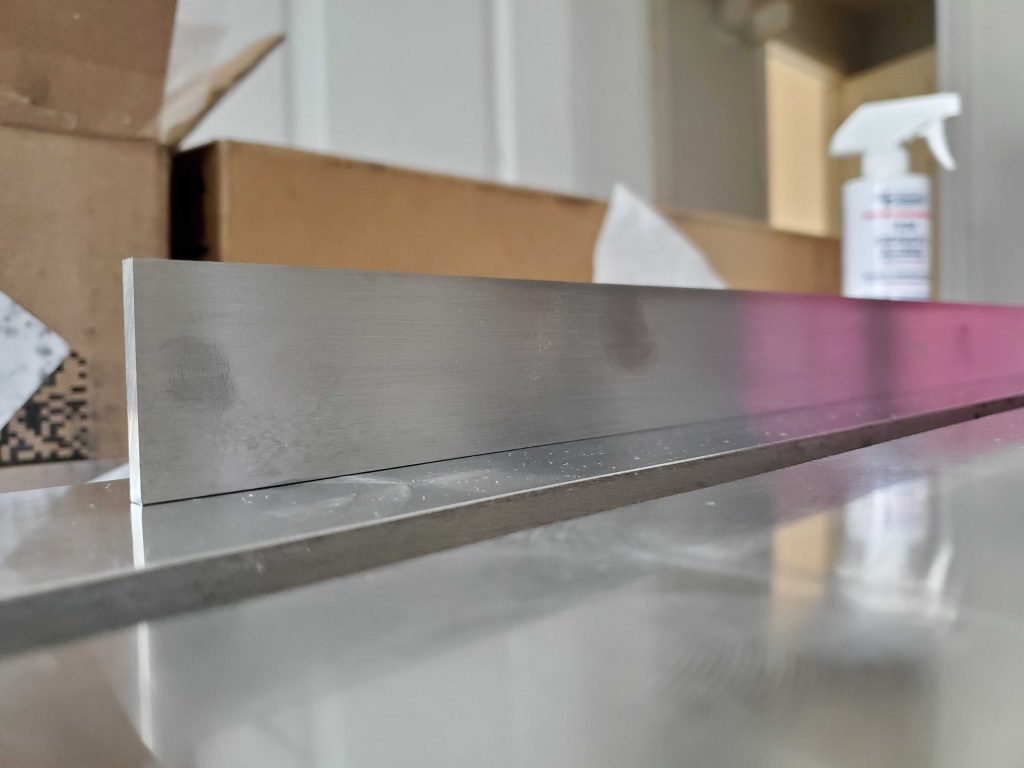

Drops from the metal yard have arrived – 1.5″ x 2.5″ 2024 bar stock, and a 1″ thick chunk of 2024 plate for the Z saddle. With a 3″ shell mill on the Bridgeport, I machined flat (ish) one side of the bar stock. My milling setup could have been better for sure, as I did get some ‘lift’ at the two ends that were outside of the vice and held up by 1-2-3 blocks and machinist jacks. Also could have been an effect of relieving stress in the bar stock. The side rails will be held on with ten M10 flat head cap screws so there will be significant force to hold it to the column and flatten it back out, hopefully not distorting the column too much in the process. The imperfect flatness can be seen against a 24″ straight edge.

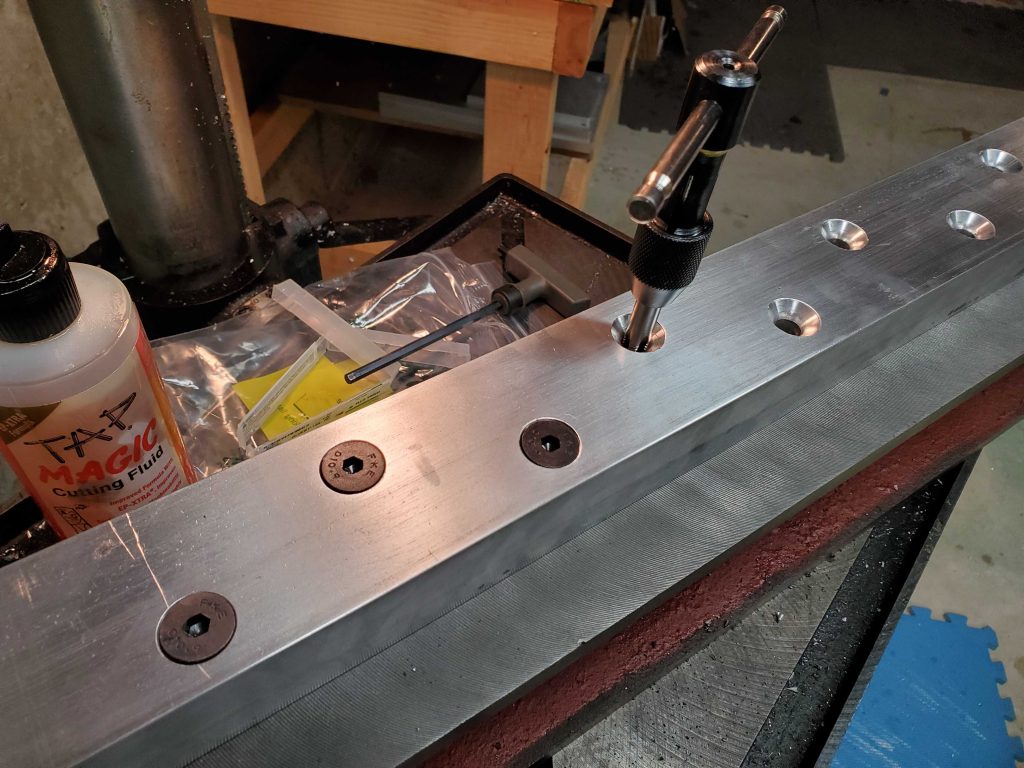

I decided to use manual layout and my drill press for the M10 countersunk bolt holes, rather than set everything up in the Bridgeport. It would have been more accurate for sure, but this was a more expedient way to get results.

Once drilled, I was able to use the side bars as guides for a transfer punch, and get the sides of the column laid out and drilled. The side bars could also be used as a tap guide once drilled.

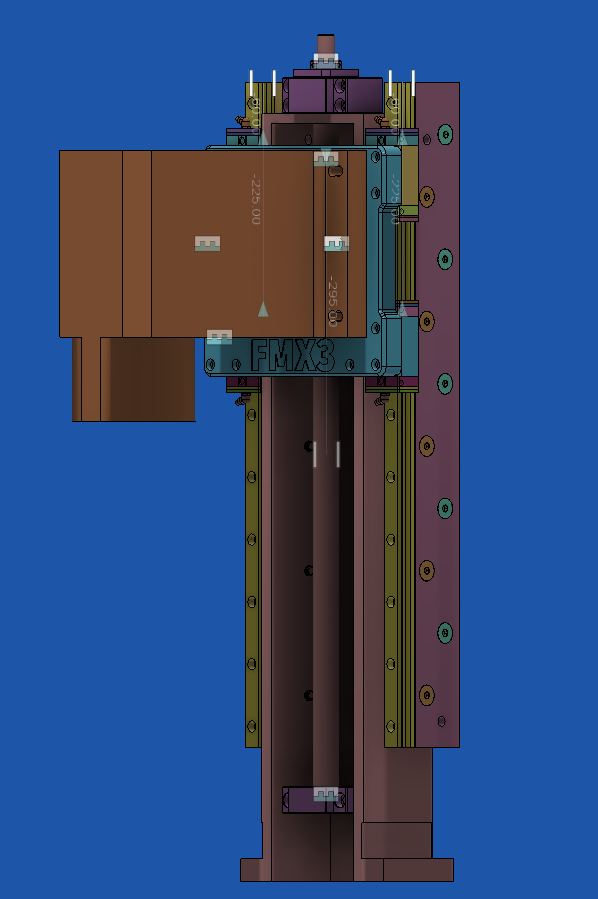

Once all the drilling and tapping was done, I did a quick test fit of the column back on the machine. Sometimes I find it valuable to see things in real life after staring at CAD for a while…