I converted my milling machine over to CNC back in late 2009. For most of the time since then, I’ve avoided the project of properly finishing up the electronics that run the machine. Last winter, I gutted the electronics of the machine, redesigned the system, created a number of circuit boards, and set about revamping. I got things mostly up and running with the brand new electronics, but again I got distracted by the time good weather rolled around and the project sat dormant for months.

This winter I decided I had to get this project done, as the delicate electronics were lying around on the bench, subject to detah by flying metal chips and other terrible fates. Just before Christmas, I finally picked up the project again, and after a fair amount of effort over the last month, I’ve finally pushed this project over a finish line. No project is ever truly done, but this one is finally wrapped up enough to be useful as it is, and it leaves room to comfortable change or expand it more in the future.

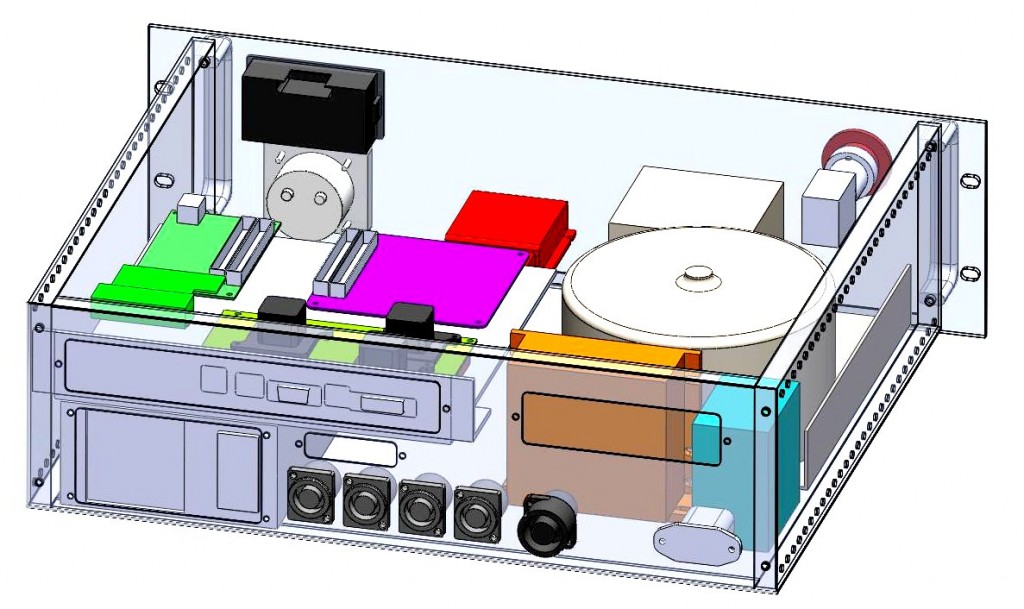

Today I put together a fairly epic length mini-documentary about the electronics, going into lots of detail about the internals. It’s probably a total snoozefest for most people, but hopefully it’s informative and will give someone else some interesting ideas for their own conversion. Enjoy!

Hey again Steve,

If you could get Neutrik connectors free, which ones would you choose for this type of CNC build? Thanks!

Four pole Speakon style:

http://www.neutrik.com/en/speakon/fc-series/nl4fc

http://www.neutrik.com/en/speakon/speakon-chassis-connectors/speakon-chassis-connectors/

You mention that your new main board is able to generate faster pulses. Do you know the rate ???khz.

I’m shopping for a controller and have seen numbers from 30khz to 2mhz and don’t know how much is needed. Or how much my drivers can take.(DM860)

Thank you for your help in advance.

Russ