Project Frankenmill – Part 16, Predator Vision

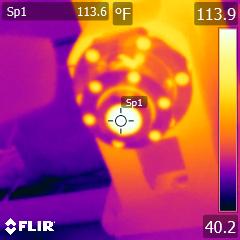

In my talking with Tormach, I asked about a spindle break-in procedure. They told me it should have already been done, but it wouldn’t harm anything to…

Project Frankenmill – Part 17, Tram

Tonight I did some very preliminary measuring for tramming the head and column. Mostly just practice to start wrapping my head around it. I started with the…

Project Frankenmill – Part 18, Shimming

Tried a little shimming of the head this morning, and I think I managed to correct the fore-aft error. Before fixing it was out 0.004 to 0.005″…

Project Frankenmill – Part 19, Life is Not Linear

Wow. It’s been almost a decade since my last update on this project. Not long after I grafted the Tormach 770 head onto my X3, I ended…

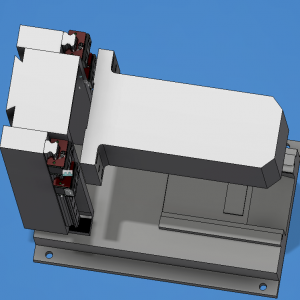

Project Frankenmill – Part 20, Choose Wisely

I mainly considered two approaches to mounting rails to the column. Approach 1 – add some kind of additional side supports to the existing column and mount…

Project Frankenmill – Part 21, Milling and Drilling

Drops from the metal yard have arrived – 1.5″ x 2.5″ 2024 bar stock, and a 1″ thick chunk of 2024 plate for the Z saddle. With…

Project Frankenmill – Part 22, Taken for Granite

For extra security, I decided to epoxy the side bars to the column so they would not move. I figured the epoxy would also help fill in…

Project Frankenmill – Part 23, Rails Without Fails

Now on to the critical milling to create the mounting surfaces and reference edges for the linear rails. First thing in the morning, I spent a ton…

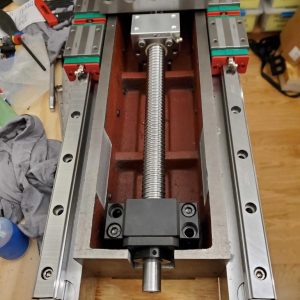

Project Frankenmill – Part 24, We’re Screwed

I considered re-using the original Thomson 16mm 0.200″ pitch ball screw from my original CNC conversion kit, but the ball nut wasn’t sounding particularly good after the…

Project Frankenmill – Part 25, Moving and Grooving

The original CNC conversion had a NEMA23 stepper located on the bottom of the column, driven by a timing belt and pulleys with a 2:1 ratio. I’m…

Project Frankenmill – Part 26, Wicked Waterjet Work

Now onto making the stepper mounting plate for the new Z axis stepper motor. We recently got a fun new toy at our makerspace, a ProtoMax waterjet….

Project Frankenmill – Part 27, So Shiny

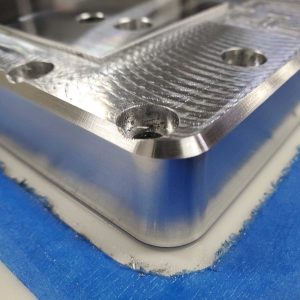

Had some time the other evening to do the final machining on the new stepper mount, on the Tormach 1100. Being able to rough cut it on…

Project Frankenmill – Part 28, The Home Stretch

I used the “saw” feature of the Protomax waterjet to cut stock to rough size for the head mounting plate the other night. At the moment we…

Project Frankenmill – Part 29, More Machining and Motion

Had some productive time in the shop during the holiday. First step was to make the counterbores for the M6 cap screws a bit deeper. Easy to…

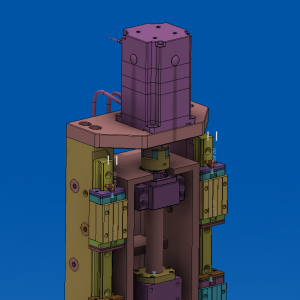

Project Frankenmill – Part 30, Do You Even Lift Bro?

Hauled the column back down to the shop and mounted it back on the machine. Sure is a lot heavier than it used to be! Muscling things…